Exploring RMS3D's Manufacturing Solutions

- MapLeo Design

- Sep 4

- 4 min read

In today's fast-paced industrial landscape, manufacturing companies must adopt cutting-edge technologies and efficient processes to stay competitive. rms3d manufacturing services offer a comprehensive range of solutions designed to meet the evolving needs of various sectors. From precision engineering to rapid prototyping, rms3d stands out as a reliable partner for businesses seeking quality and innovation.

Understanding rms3d Manufacturing Services

rms3d manufacturing services encompass a broad spectrum of capabilities that cater to diverse industrial requirements. These services include 3D printing, CNC machining, injection molding, and product design consultation. By integrating advanced machinery with skilled craftsmanship, rms3d ensures that every project meets stringent quality standards.

One of the key strengths of rms3d is its ability to handle both small-scale prototypes and large production runs. This flexibility allows clients to test concepts quickly and scale up manufacturing without changing vendors. For example, a startup developing a new consumer gadget can use rms3d's rapid prototyping to create functional models, then transition seamlessly to mass production once the design is finalized.

Key Features of rms3d Manufacturing Services

Precision and Accuracy: Utilizing state-of-the-art equipment to achieve tight tolerances.

Material Variety: Working with plastics, metals, composites, and more.

Customization: Tailored solutions to meet specific client needs.

Speed: Fast turnaround times without compromising quality.

Sustainability: Eco-friendly practices to reduce waste and energy consumption.

These features make rms3d a preferred choice for industries such as automotive, aerospace, healthcare, and consumer electronics.

Advantages of Choosing rms3d Manufacturing Services

Selecting the right manufacturing partner can significantly impact product success. rms3d manufacturing services offer several advantages that help businesses optimize their production processes.

Cost Efficiency

By leveraging advanced manufacturing techniques, rms3d reduces material waste and minimizes labor costs. For instance, additive manufacturing (3D printing) builds parts layer by layer, using only the necessary material. This approach contrasts with traditional subtractive methods that often generate excess scrap.

Quality Assurance

rms3d employs rigorous quality control protocols at every stage of production. This includes dimensional inspections, material testing, and functional assessments. Clients receive detailed reports ensuring that products meet or exceed specifications.

Innovation and Flexibility

The integration of digital design tools and automated machinery allows rms3d to adapt quickly to design changes. This agility is crucial in industries where product iterations are frequent. Moreover, rms3d supports complex geometries and intricate designs that might be challenging for conventional manufacturing.

Expert Support

Beyond manufacturing, rms3d offers consulting services to optimize product design for manufacturability. This collaboration helps reduce costs, improve performance, and shorten time-to-market.

rms3d's Role in Advancing Manufacturing Technology

The manufacturing sector is undergoing a transformation driven by digitalization and automation. rms3d is at the forefront of this change, incorporating Industry 4.0 principles into its operations.

Smart Manufacturing

rms3d utilizes IoT-enabled devices and real-time data analytics to monitor production lines. This approach enhances efficiency by predicting maintenance needs and minimizing downtime.

Additive Manufacturing Excellence

With expertise in various 3D printing technologies such as SLS, SLA, and FDM, rms3d can produce complex parts with high precision. This capability opens new possibilities for lightweight structures and customized components.

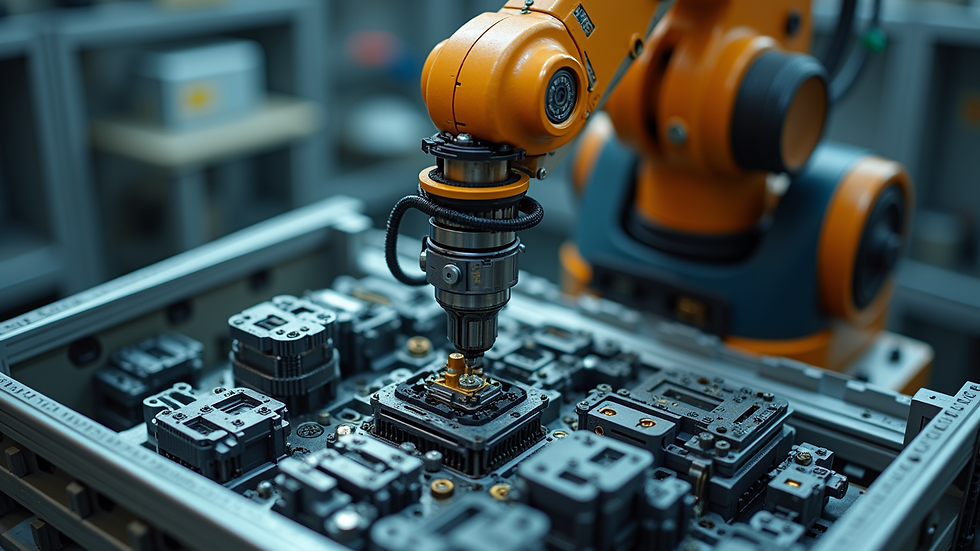

Collaborative Robotics

Automation at rms3d includes collaborative robots (cobots) that work alongside human operators. Cobots handle repetitive tasks, allowing skilled workers to focus on quality control and innovation.

How rms3d Supports Diverse Industries

rms3d manufacturing services cater to a wide range of sectors, each with unique demands.

Automotive Industry

Precision and durability are critical in automotive parts. rms3d produces engine components, interior fittings, and prototype models that meet stringent safety and performance standards.

Healthcare Sector

Medical devices require biocompatible materials and exact specifications. rms3d manufactures surgical instruments, prosthetics, and diagnostic equipment with high reliability.

Consumer Electronics

Rapid product cycles and intricate designs characterize this industry. rms3d's rapid prototyping and small-batch production help companies launch innovative gadgets quickly.

Aerospace

Lightweight and strong materials are essential for aerospace applications. rms3d delivers components that withstand extreme conditions while reducing overall weight.

For businesses looking to partner with a trusted manufacturer, rms3d changodar offers a strategic location and advanced infrastructure to support large-scale projects efficiently.

Maximizing Your Manufacturing Potential with rms3d

To fully benefit from rms3d manufacturing services, consider the following actionable recommendations:

Engage Early in the Design Process: Collaborate with rms3d engineers during product development to optimize designs for manufacturability.

Leverage Prototyping: Use rapid prototyping to test and refine concepts before committing to full production.

Choose the Right Materials: Consult with rms3d experts to select materials that balance cost, performance, and sustainability.

Plan for Scalability: Design products with future production volumes in mind to avoid costly redesigns.

Implement Quality Checks: Establish clear quality criteria and inspection protocols with rms3d to ensure consistent output.

By following these steps, companies can reduce time-to-market, lower costs, and improve product quality.

Exploring rms3d manufacturing services reveals a company committed to innovation, precision, and customer satisfaction. Their comprehensive solutions and advanced technologies make them a valuable partner for businesses aiming to excel in today's competitive manufacturing environment. Whether you need rapid prototyping or full-scale production, rms3d provides the expertise and infrastructure to bring your ideas to life efficiently and reliably.

Comments